3D Printing in Space is Now Possible Thanks to Startup Made in Space

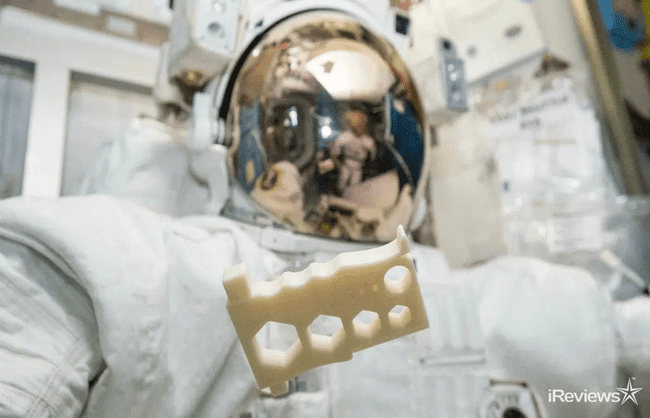

3D printing in space is complicated. Between the lack of gravity, lack of air, and other obstacles, getting a 3D printer to work in space is nothing short of miraculous. A startup named Made in Space is helping astronauts do just that. The company developed a method to 3D print outside of the International Space Station (ISS). Astronauts can repair, upgrade, and prototype without having to go inside a space capsule.

NASA studies 3D printing in space because they know about the immense benefits this technology could provide them. They were looking for a way to produce materials for upgrades or repairs on the spot, even if the need is outside of the ISS. Thus far, NASA has only achieved 3D printing inside the ISS. This new method developed by Made in Space will save NASA and other government space agencies countless hours and money.

Manufacturing out of This World

The company’s innovative technology uses polyetherimide/polycarbonate — known as PEI/PC, brand name ULTEM. This material is stronger than anything astronauts currently use. It’s also “resistant to the UV environment, [and] resistant to atomic oxygen, so it can perform actual uses in space” according to Matt Napoli, Vice President of Made in Space.

The startup hopes to enable astronauts to take much fewer supplies into space. The printer has the potential to “give researchers the ability to prototype tools and designs in the environment of space with short iteration cycles.”

Made in Space was the first company to launch and deliver a 3D printer to the ISS. The printer underwent 20,000 hours of testing at NASA before launching into space. That’s around 834 days of 24/7, round-the-clock printing. The test was so successful that NASA felt it was safe enough to launch sooner than originally anticipated.

After the first successful mission, Made in Space delivered another printer and created the Additive Manufacturing Facility (AMF). The company is working on a multiple-armed 3D printing robot, called the Archinaut, among other things, like fiber optics for space. Archinaut is still under test, but the company plans to release it in 2018. It is meant to operate fully outside of the ISS.

Printing in Pink

In an interesting marketing campaign, Made in Space is partnering with Susan G. Komen to fundraise with Pippa Mann. Mann, the first British woman to compete in the Indianapolis 500, is the face of the fundraising campaign.

Made in Space will print the breast cancer foundation’s pink ribbon logo at the AMF. Then, the ribbon will be auctioned off, and proceeds will be donated to the foundation. Susan G. Komen says proceeds will benefit community outreach and research programs.

Mann says, “When Made In Space reached out to me with their concept for this partnership, they immediately captured my attention and imagination. I’m so geeked out by this.”

“The idea to tie these two promotions together in this way hit the cool factor out of the park. … I’m so excited to have these guys on board, and to be part of producing this breast cancer ribbon in space this October!”

– Mann

The AMF prints the Susan G. Komen pink ribbon in October. But it will probably get auctioned in 2018. 3D printing takes longer in space than it does on Earth, and the ribbon will take some time to reach Earth.

Made for Space in Space

Made in Space has to test new designs on Earth to establish the best printer settings first. When the AMF subsequently receives the files, it 3D prints the design. Then the newly printed pieces are packaged in special bags until they can hitch a ride on the next flight to Earth.

The AFM has already tested 3D printing on the ISS. Some things are small, some are medical supplies. More varieties are being printed every day. Made in Space is already the first ever commercial manufacturing service in space. Eventually, the company could 3D print satellites while the ISS is in orbit.

Until we’re all in space and able to 3D print things on the fly for our space suits, we’ll stick to one of our favorite low-budget 3D printers here on Earth.

Sources: 3D Print