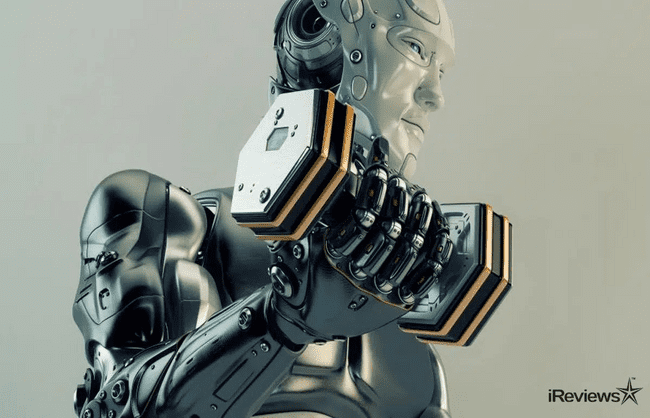

Synthetic Muscle Brings Lifelike Robots Closer to Reality

Artificial intelligence (AI) has made headlines nearly every day this year. Jaguar wants AI not behind the steering wheel, but in it. LG is working on a smart mower robot for your lawn. And Microsoft recently revealed Brainwave, their solution for real-time AI. But now, Columbia University researchers are figuring out how to enable robots to “flex their muscle” in a different, more literal way.

Catching Robot Bodies Up to Their Brains

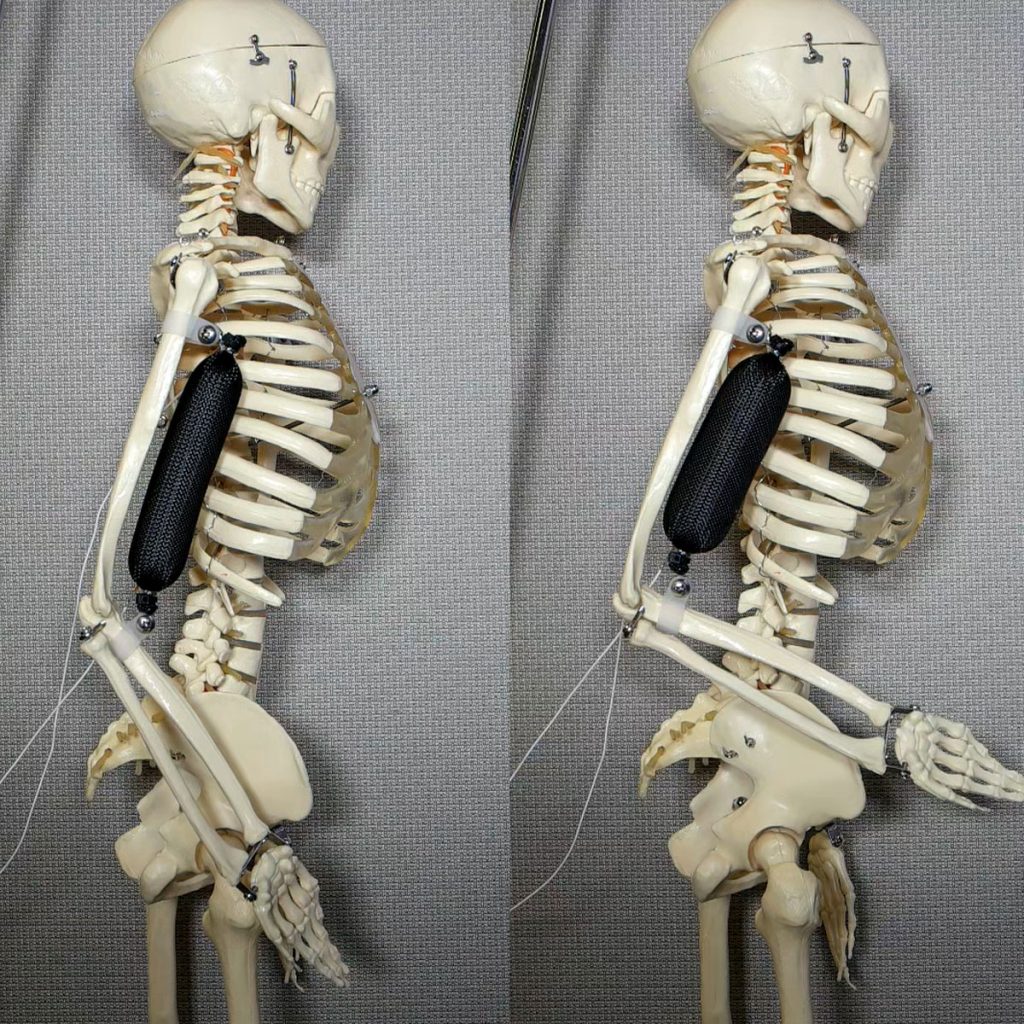

Robots are getting incredibly smart these days. But they still cannot handle simple tasks that humans take for granted. Picking something up without crushing it and having a natural, fluid motion are two examples. This inability to act as a “soft muscle” stops robots from interacting with humans more closely in environments like manufacturing or healthcare.

A Columbia University engineering team have created a synthetic material that is capable of acting like a soft muscle. Led by mechanical engineering Professor Hod Lipson, the team took inspiration from living organisms. Lipson explains: “We’ve been making great strides toward making robots minds, but robot bodies are still primitive. This is a big piece of the puzzle, and, like biology, the new actuator can be shaped and reshaped a thousand ways.”

The synthetic muscle material, which can be 3D printed, could revolutionize soft material robotics. Besides AI, robots have made advances in movement. But these are mostly in rigid robotics, where delicacy is an afterthought. This new muscle could make robots more ubiquitous in our everyday lives as well as make lifelike robots a reality instead of a science fiction idea.

“We’ve overcome one of the final barriers to making lifelike robots.”

– Professor Hod Lipson

Soft to the Touch

The soft muscle is actually a self-contained actuator. Other robotic solutions usually utilize hydraulic or pneumatic inflation for action. The synthetic muscle doesn’t need any external pressure regulators or equipment.

Because the actuator is self-contained, this new material could open up the possibility for robots that are smaller and more autonomous in operation when used in tandem with AI and other improvements. No longer will machines be relegated to designated areas.

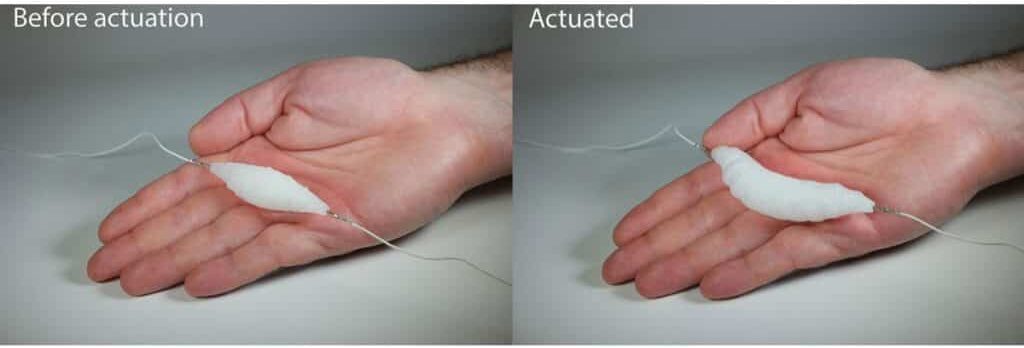

A thin resistive wire coupled with a low-power current electrically actuates the material. This causes the material to expand to nine times its resting size. The material is three times stronger than human muscle and can lift up a thousand times its own weight. It also possesses a strain density that is fifteen times the average of natural muscle.

The material itself is made from a silicone rubber matrix with ethanol microbubbles sprinkled throughout. This allows for the actuator to handle high strain and stress but maintain a low density. Aslan Miriyev, postdoctoral researcher and lead author of the research, explains the material’s versatility: “It can push, pull, bend, twist, and lift weight. It’s the closest artificial material equivalent we have to a natural muscle.”

Minding the Muscle

The muscle material was deliberately designed not only to be easy to make, but to also be cheap and environmentally-conscious. Some kinks are still being worked out for the next iteration. The research group hopes to replace the small resistive wire with a conductive material. This would improve the actuator’s longevity and response time.

After that, the group would like to incorporate AI to control the muscle’s motion and make it more human-like. They see a bright future with a variety of uses for their synthetic muscle. “Our soft functional material may serve as robust soft muscle, possibly revolutionizing the way that soft robotic solutions are engineered today.” said Miriyev.

Robots would be able to be closer to humans as well as act more like them in movement as well as thought. It’s exciting to think that the next time you are in the clinic or inside a factory, intelligent robots that resemble humans could be assisting in the work being done.

Looking to flex your robotic engineering abilities? Check out our reviews for the DOBOT M1 and uArm Swift Pro. Check out iReviews often for the latest and greatest in disruptive tech news and reviews.

Sources: The Telegraph, EurekAlert, Futurism